What You Need to Know about High Temp Gaskets?

1. Temperature Range: High-temp gaskets are engineered to withstand a wide range of temperatures, typically above 500°F (260°C). The specific temperature range varies depending on the material used. It is crucial to select a gasket material that can handle the specific temperature requirements of the application.

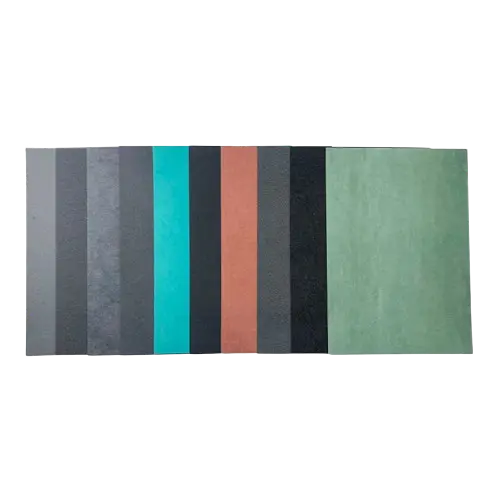

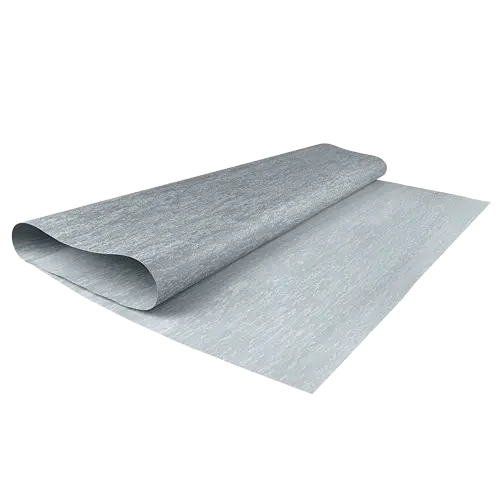

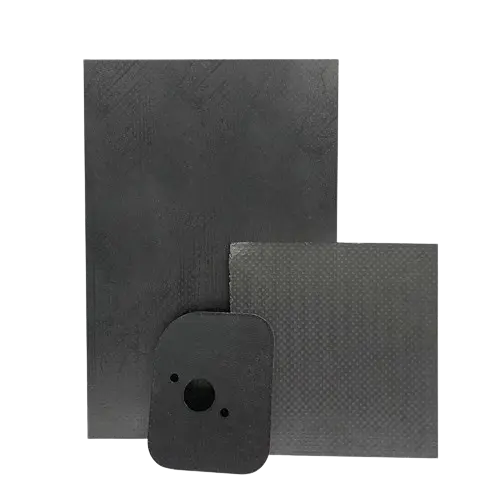

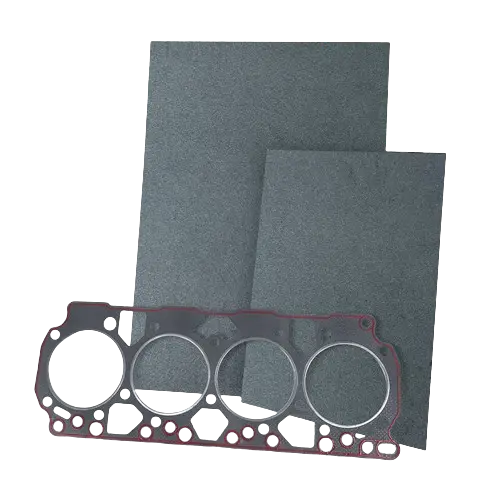

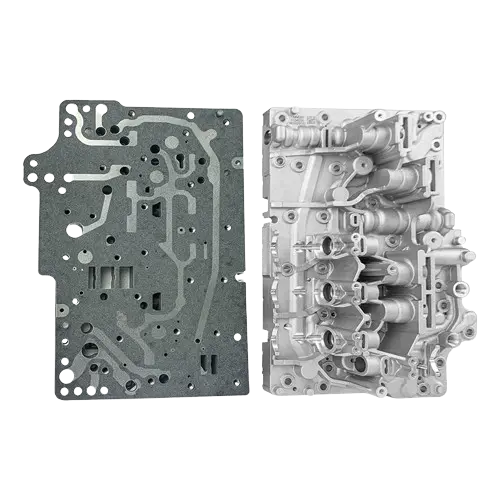

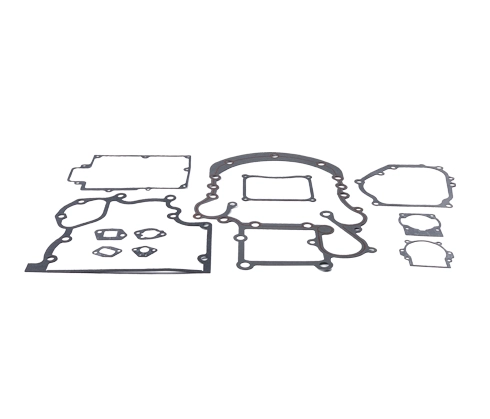

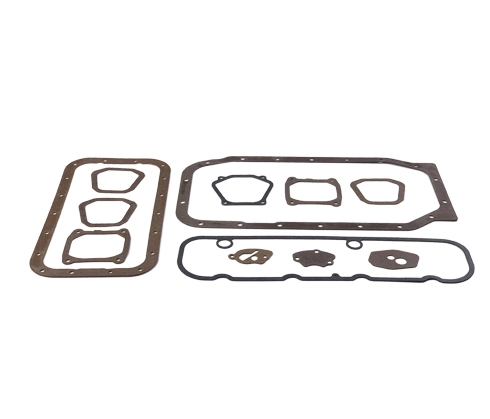

2. Material Options: High-temp gaskets are available in various materials, each with its own temperature resistance and performance characteristics. Common materials include graphite, ceramic fiber, metal (such as stainless steel), and PTFE (Teflon). The choice of material depends on factors such as temperature, pressure, chemical compatibility, and application requirements.

3. Sealing Performance: High-temp gaskets are designed to provide a reliable and durable seal even under extreme temperature conditions. They must be able to withstand thermal expansion and contraction, maintain their shape, and resist degradation or loss of sealing properties at high temperatures. Proper installation and torquing procedures are essential to ensure an effective seal.

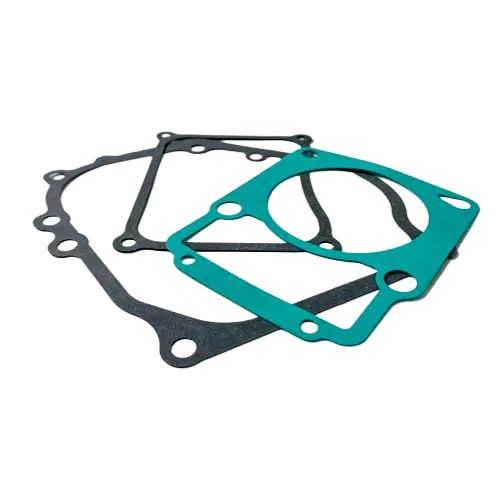

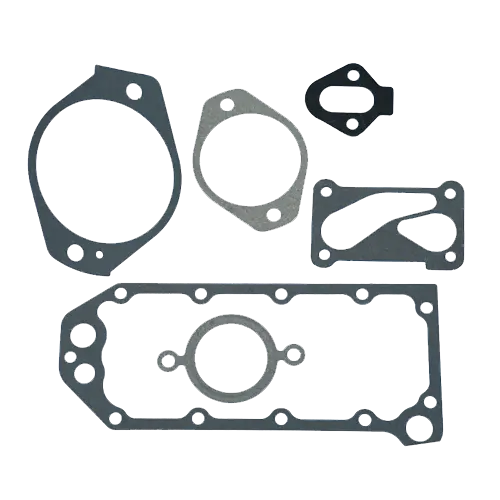

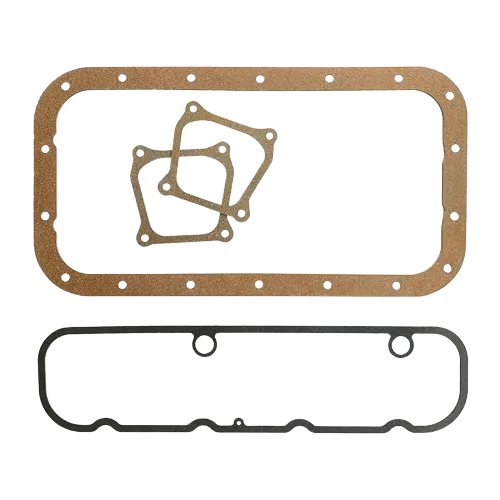

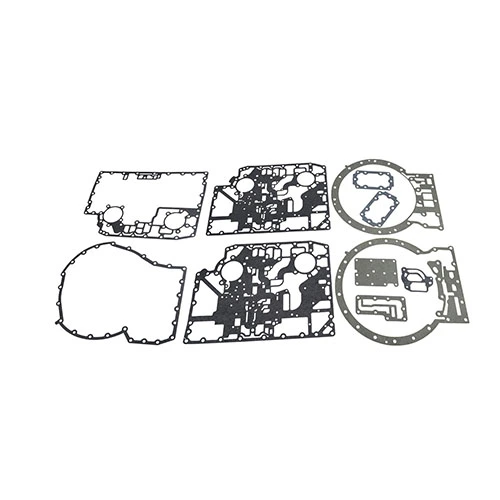

4. Applications: High-temp gaskets are used in a wide range of industries and applications where elevated temperatures are present. Some common applications include exhaust systems, boilers, furnaces, heat exchangers, automotive engines, and high-temperature processing equipment in industries such as power generation, oil and gas, chemical processing, and aerospace.

5. Considerations: When selecting a high-temp gasket, it is important to consider factors such as temperature range, pressure, chemical compatibility, flange surface conditions, and installation requirements. It is recommended to consult with gasket manufacturers or experts to ensure the appropriate gasket material and design are chosen for the specific application.

Overall, high-temp gaskets play a critical role in maintaining a reliable seal in applications exposed to elevated temperatures. Proper selection, installation, and maintenance of these gaskets are essential to ensure optimal performance, safety, and longevity in high-temperature environments.

High Temp Gaskets: Essential for High Heat Applications

High-temperature gaskets are used in a wide range of high-heat applications across various industries. Some common examples include:

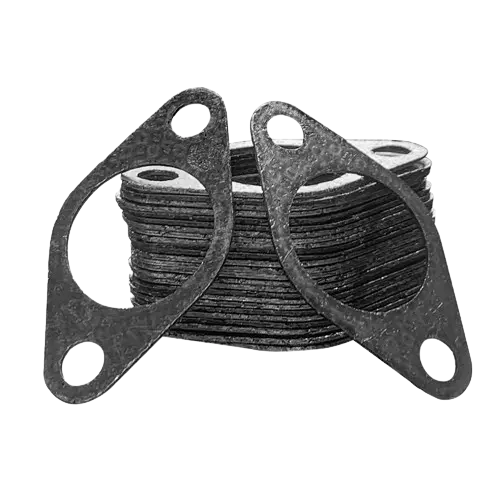

1. Exhaust Systems: High-temp gaskets are crucial in automotive and industrial exhaust systems, where they seal connections between exhaust manifolds, catalytic converters, mufflers, and pipes. These gaskets withstand the high temperatures generated by engine exhaust gases.

2. Boilers and Furnaces: High-temp gaskets are used in boilers and furnaces to seal flange connections, access doors, and inspection ports. These gaskets ensure a tight seal to prevent heat loss and maintain efficient operation in high-temperature environments.

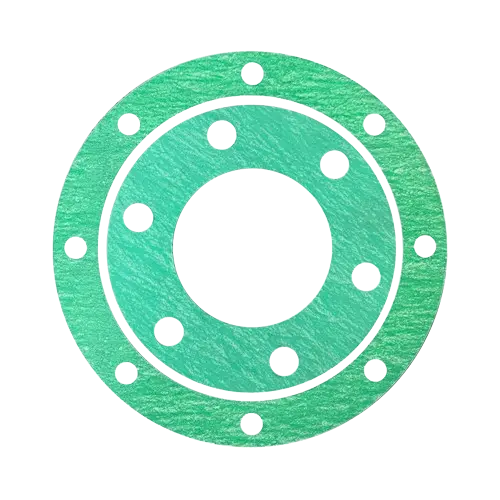

3. Heat Exchangers: High-temp gaskets are employed in heat exchangers, which transfer heat between fluids or gases. They seal the connections between heat exchanger plates or tubes, ensuring efficient heat transfer and preventing leaks in high-temperature applications.

4. Power Generation: High-temp gaskets are essential in power generation facilities, including thermal power plants and nuclear power plants. They are used in steam turbines, boilers, and other equipment that operates at high temperatures and pressures.

5. Chemical Processing: High-temp gaskets find application in chemical processing plants, where they seal connections in reactors, distillation columns, pumps, valves, and other equipment. These gaskets withstand the high temperatures and corrosive chemicals present in the processing environment.

6. Aerospace: High-temp gaskets are used in aerospace applications, such as aircraft engines and rocket propulsion systems. They seal critical connections and components exposed to high temperatures during operation.

7. Industrial Ovens and Furnaces: High-temp gaskets are employed in industrial ovens and furnaces used for heat treatment, baking, drying, or curing processes. They seal access doors, flanges, and other openings to maintain temperature control and prevent heat loss.

8. Foundries and Metal Processing: High-temp gaskets are used in foundries and metal processing facilities to seal connections in furnaces, ladles, and other equipment involved in high-temperature metal melting, casting, and forging processes.

These are just a few examples of the many applications where high-temperature gaskets are essential. The specific choice of gasket material and design depends on the temperature range, pressure, chemical compatibility, and other factors specific to each application.

English

English Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português